Researchers draw inspiration from nature to create tiny, powerful microlenses for advanced image sensors.

Beneath the ocean’s surface, simple marine animals called sea sponges grow delicate glass skeletons that are as intricate as they are strong. These natural structures are made of a material called silica—also known as bioglass—that is both lightweight and incredibly durable, allowing the sea sponges to thrive in harsh marine environments.

Now, scientists at the University of Rochester have replicated this remarkable material in the lab, using bacteria and enzymes from sea sponges to create tiny microlenses that mimic the sea sponge’s natural ability to combine strength and lightness. In a paper published in the journal PNAS, the team—including scientists from the University of Colorado–Boulder, Delft University of Technology, and Leiden University—reports that the bioinspired material could pave the way toward specialized image sensors for medical and commercial uses. By applying the remarkable properties of sea sponges, the researchers unlock new possibilities for creating sustainable and efficient materials that mimic the natural world.

“This research is the first to engineer light-focusing properties into bacteria cells, and I am excited to explore the different possibilities that our work has opened up,” says Anne S. Meyer, an associate professor in Rochester’s Department of Biology.

What is a microlens?

A microlens is a very small lens that is only a few micrometers in size—about the size of a single cell in your body. Microlenses are designed to capture and focus or manipulate light into intense beams at a microscopic scale.

Because of their small size, microlenses are typically difficult to create, requiring complex, expensive machinery and extreme temperatures or pressures to shape them accurately and achieve the desired optical effects.

When Meyer learned about the enzymes that sea sponges use to make their glass skeletons—and that the glass structures had excellent optical properties—“it seemed like a perfect basis for a synthetic biology project,” she says.

Collaborative innovation across disciplines

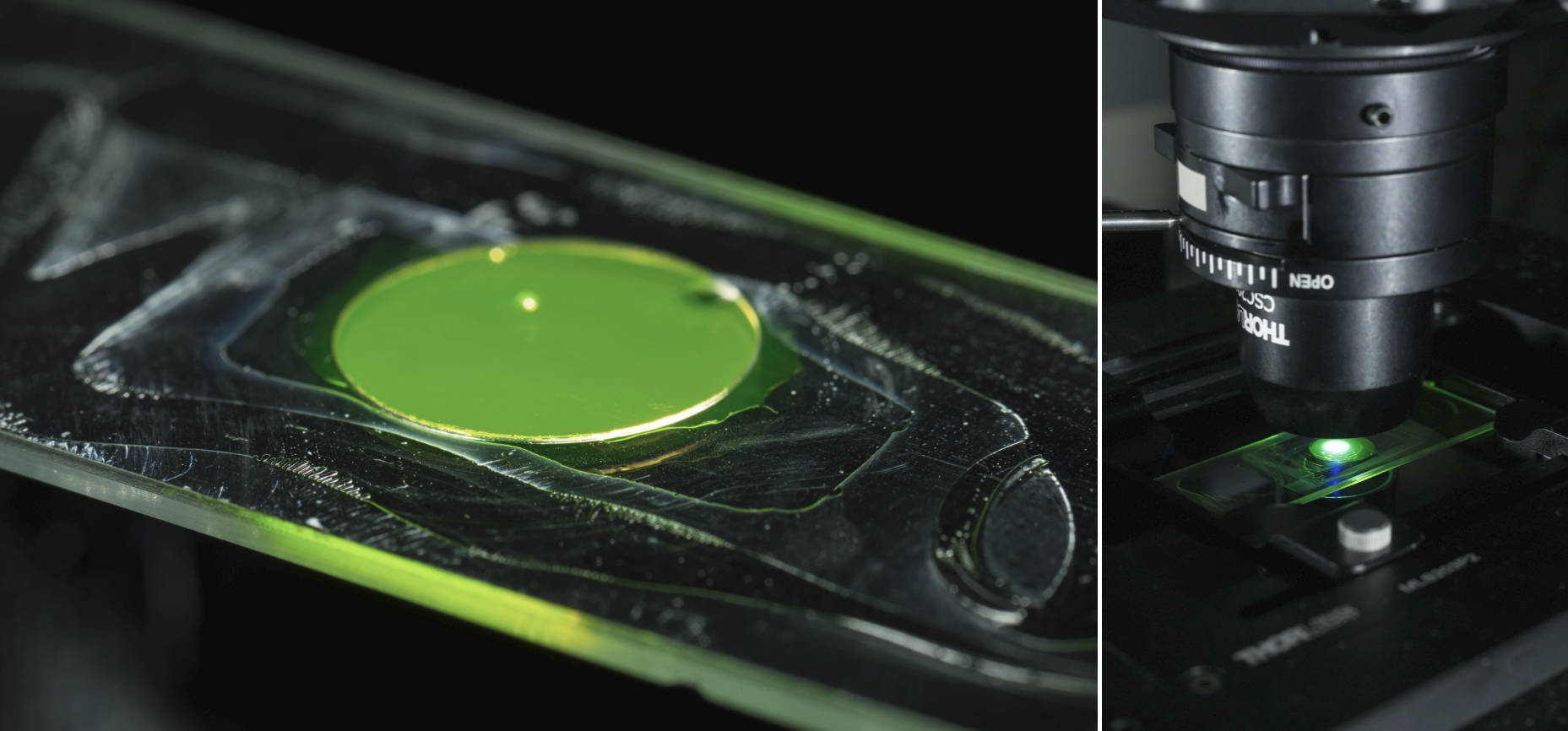

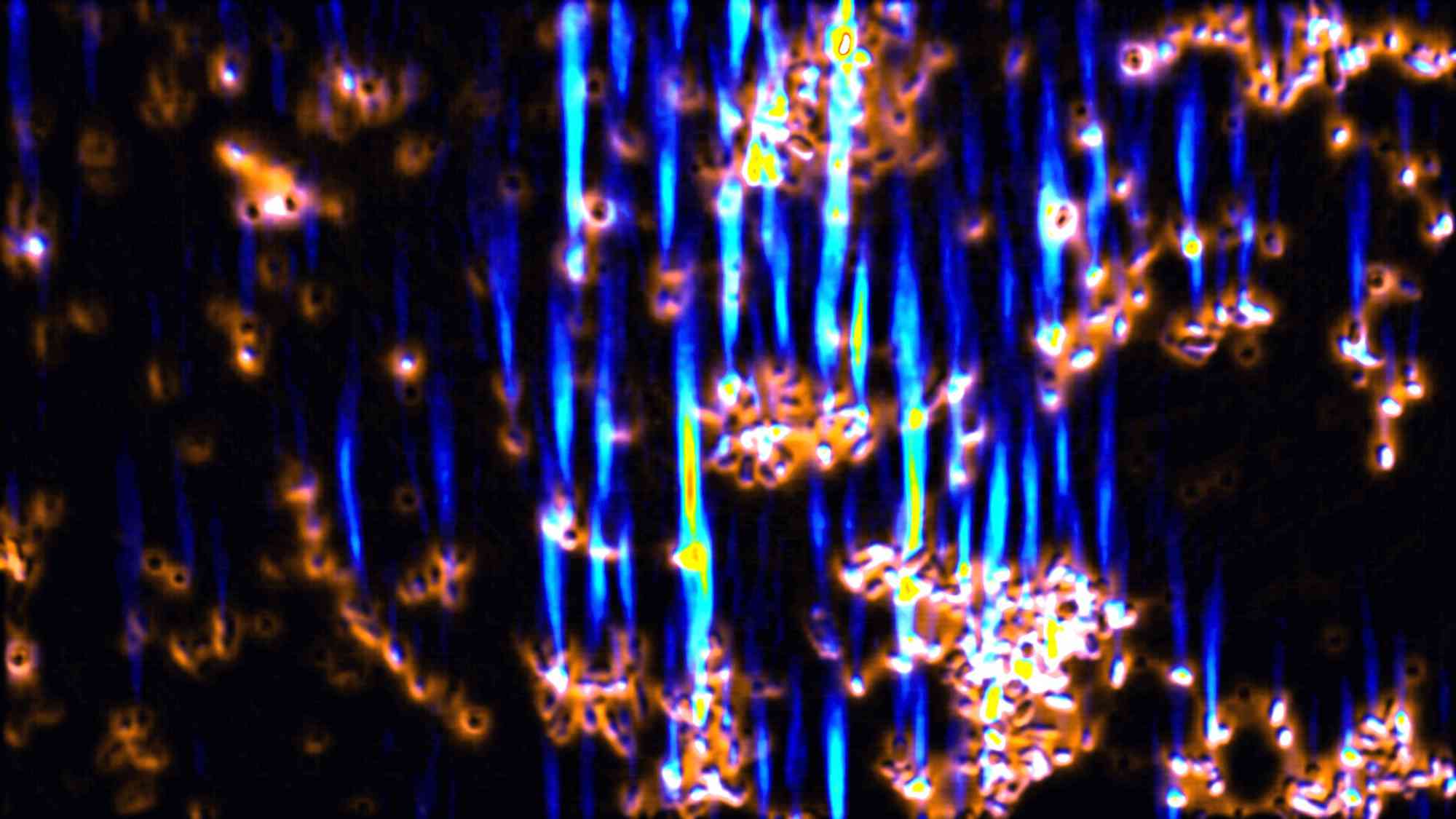

Meyer teamed up with experts across multiple disciplines, including optics, physics, and chemistry. Her lab engineered bacteria cells to express the silicatein enzyme from sea sponges, which the animals use to mineralize silica-based glass. They also developed a novel microscopy technique to measure the optical properties of the bacteria cells. In collaboration with material scientists at the University of Colorado–Boulder, Meyer ensured that silica was present on the engineered cells by analyzing the bacteria’s chemical properties. She also worked with faculty members Greg Schmidt and Scott Carney at Rochester’s Institute of Optics to create mathematical models that predicted the optical properties of the glass-coated cells.

The result? Bacterial microlenses that are much smaller than typically produced microlenses.

Because the microlenses are created by bacterial cell factories, they are inexpensive and easy to grow, and they can create their glass coating at standard temperatures and pressures.

“These properties make them well-suited for a unique range of applications,” Meyer says.

Small lenses, big potential

What are the benefits of a microlens? The tiny size of the bacteria-based microlenses makes them ideal for creating higher-resolution image sensors that go beyond current capabilities. The microlenses could, for instance, allow clinicians to visualize smaller structures with greater clarity. Since the glass-coated bacteria focus light into very bright beams, they have the potential to enhance conventional microscopy by enabling the imaging of objects that are currently too small to be visualized, such as small subcellular features.

The glass-coated bacteria remain alive for several months after glass encapsulation, making them living optical devices that could be used to sense and respond to their environment by changing their optical properties.

These characteristics make the microlenses attractive for other environments as well: Meyer and a team of her colleagues recently received a grant from the Air Force Office of Scientific Research to study the effects of the materials in low-gravity environments.

“The ease of producing these microlenses could make them a good way to fabricate optics in locations with less access to nanofabrication tools, including outer space,” Meyer says.