Researchers have synthesized highly durable solar cells made from perovskite — a common crystal structure (in its natural form a calcium titanium oxide mineral) — in a breakthrough that could revolutionize the solar industry.

Solar power is the fastest-growing energy technology and plays a key role in cutting greenhouse gas emissions. Solar power converts sunlight into electricity — and is used in various applications including lighting, heating, cooling, computers, electronics and powering machinery.

Solar panels made from silicon have a lifetime of around 25 years. It is tried and tested, but using silicon is environmentally unsustainable because it is a non-renewable, finite resource. The most durable solar panels, for example, use pure silicon, which is costly and inefficient to produce.

In recent years, perovskites have shown promise as a cheaper, less wasteful material, the scientists said, but have far less durability. Natural perovskites are rare but can be synthesized artificially as an organic-inorganic compound with an ABX3 crystal structure harboring electrically charged ions.

Related: 32 weird technologies that never took off

They work as an active light-harvesting layer like those found in solar technologies today. But they are not commercially viable because they have a lifetime measured in just months. They are also prone to chemical and thermal instability, and problems can arise during production (they are susceptible to damage by moisture and oxygen).

Scientists aimed to tackle these stability issues by creating new design strategies, publishing their findings in a study published June 13 in the journal Science. They created a new structure from perovskites that can theoretically last as long as silicon-based solar cells.

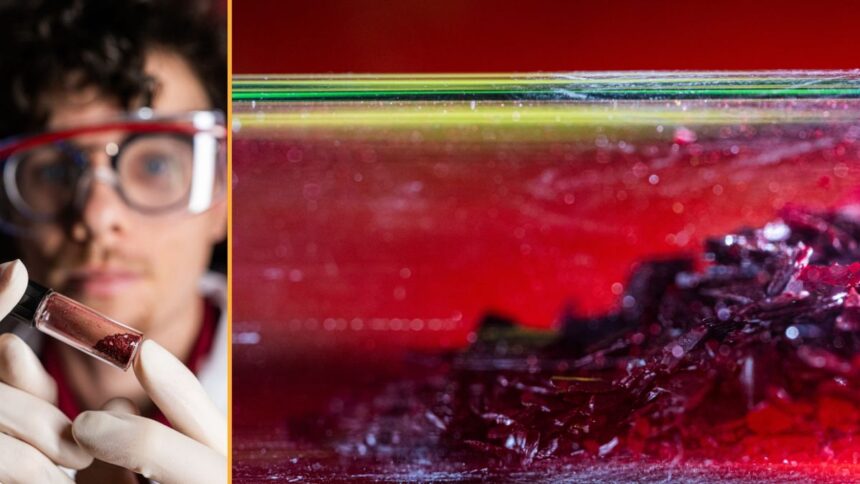

“Perovskite solar cells are kind of the holy grail of this new solar cell technology. And that’s because perovskites can be made in theory significantly cheaper than inorganic solar cells like silicon or gallium arsenide,” said Isaac Metcalf, graduate student of materials science and nanoengineering at Rice University. “The reason why is because they can be solution-processed at low temperatures. Basically, you can take an ink of a perovskite precursor and you can spread it across a piece of glass, and then heat it up, and then you have a perovskite.”

Building on past research and other recent studies that sought to improve stability, the team focused on formamidinium iodide, a precursor in the fabrication of perovskite solar cells (known for its enhanced properties of light absorption and thermal stability).

They introduced a soluble form of the precursor to a layer of 2D perovskites and exposed them to heat above 140 degrees Fahrenheit (60 degrees Celsius). This is a temperature at which the stability of formamidinium iodide-based solar cells is known to be limited. Exposure for a long time means the team generated “ultra-stable” 3D perovskites.

Importantly, the new way of designing perovskites renders them amenable to solution-processing methods and means they could be produced on a grander scale. The study marks a major step forward in bringing perovskite solar cells to maturity, the scientists said.