Developing next-generation energy storage technologies that can deliver both high power and high capacity at the same time.

A research team led by Dr. Bon-Cheol Ku and Dr. Seo Gyun Kim from the Carbon Composite Materials Research Center at the Korea Institute of Science and Technology (KIST), along with Professor Yuanzhe Piao of Seoul National University (SNU), has developed a high-performance supercapacitor that may represent the next generation of energy storage.

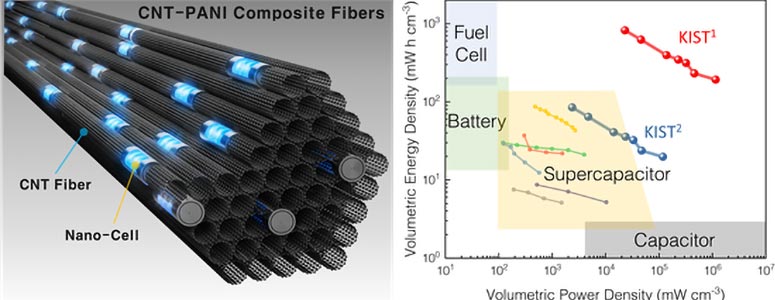

Their breakthrough addresses key limitations of current supercapacitors by using an advanced fiber structure made from single-walled carbon nanotubes (CNTs) and the conductive polymer polyaniline (PANI).

Supercapacitors charge faster and offer higher power density than traditional batteries, with minimal performance loss even after tens of thousands of charging cycles. However, their lower energy density limits how long they can operate, which has made them less practical for extended-use applications like electric vehicles and drones.

Innovative CNT‑PANI fiber structure

To address this challenge, the researchers chemically bonded single-walled carbon nanotubes (CNTs), known for their high conductivity, with polyaniline (PANI), a low-cost and easily processed conductive polymer. By combining these materials at the nanoscale, they created a complex fiber structure that improves the movement of both electrons and ions. This results in a supercapacitor capable of storing more energy and releasing it more quickly.

The new supercapacitor has demonstrated stable performance through over 100,000 charge and discharge cycles and remains effective even in high-voltage environments. Because of its durability and efficiency, the technology can serve as either a replacement or an enhancement to current battery systems. In electric vehicles, it could deliver fast-charging power that boosts both driving range and performance.

Drones and robots may also benefit from longer operation times and improved reliability. Additionally, the CNT-PANI composite fiber is highly flexible, allowing it to be rolled or folded for use in next-generation electronics like wearable devices.

Mass production and cost reduction

Another major achievement of the research is the reduction of production costs and the possibility of mass production. Despite their excellent properties, single-walled carbon nanotubes (CNTs) have been difficult to commercialize due to their high production costs, but the researchers solved this problem by compounding them with the low-cost conductive polymer polyaniline (PANI).

Furthermore, they have laid the foundation for mass production through a simple process, and recently succeeded in developing film-like structures based on this technology, further advancing commercialization. In the future, it will be utilized as a key enabling technology for the transition to a carbon-neutral society across various industries such as electric vehicles, robots, drones, and wearable devices.

“This technology overcomes the shortcomings of supercapacitors by using single-walled carbon nanotubes and conductive polymers,” said Dr. Bon-Cheol Ku of KIST. “We will continue to develop and industrialize ultra-high-performance carbon fibers based on carbon nanotubes.”

Reference: “Nanocell-structured carbon nanotube composite fibers for ultrahigh energy and power density supercapacitors” by Dongju Lee, Junghwan Kim, Chae Won Kim, Jeong-Gil Kim, Se Eun Jung, So Jeong Heo, Byeong Woo Im, Nam Dong Kim, Seo Gyun Kim, Yuanzhe Piao and Bon-Cheol Ku, 27 January 2025, Composites Part B: Engineering.

DOI: 10.1016/j.compositesb.2025.112179

This research was supported by the Ministry of Science and ICT (Minister Yoo Sang-im) through the KIST Institutional Program, Regional Innovation Leading Technology Development Project (RS-2019-NR040066), Academic Research Platform Construction Pilot Project (RS-2023-00304729), and the Ministry of Trade, Industry and Energy (Minister Ahn Duk-geun) through the Material Component Technology Development Project (RS-2023-00258521). The research was published in the latest issue of the international journal ‘Composites Part B: Engineering’ (IF: 12.7, JCR: 0.3%), and domestic and U.S. patent applications have been filed.

Never miss a breakthrough: Join the SciTechDaily newsletter.